JDA is now Blue Yonder

Formerly JDA Same Expertise A Fresh New Name

WMG

The University of Warwick

Practice

Blue

Yonder

Unique

Perspective

The diversity of our partners means we have impact across sectors including agrochemicals, automotive, defence, consumer packaged goods, retail, and pharmaceuticals. Current research areas include the circular economy, customer responsive supply chains, right-shoring, data driven decision making, and offsets and economic engagement.

Our innovative research and the industrial expertise of our teaching staff, helps to inform our postgraduate education, including both full and part-time MSc programmes. We also support PhD and EngD candidates within our expert research teams.

Our Supply Chains in Practice networking events and industrial collaborator forum engage practitioners across sectors and disciplines. Through quarterly meetings, we embed and develop customer responsive supply chain theory into practical solutions to turn rhetoric into reality. Our collaborator forum is an invited group of forward thinking companies, whilst our networking events are open to the wider supply chain community to attend.

This unique and authoritative survey draws on the experience of Supply Chain Professionals. To date over 180 manufacturers and 100 retailers have taken part.

BlueYonder Software offers the leading supply chain management (SCM) platform powered by artificial intelligence (AI) and machine learning (ML). BlueYonder’s leading cloud solutions manage supply chains from end-to-end, spanning supply chain and retail planning, execution and delivery.

Using BlueYonder’s comprehensive SCM platform and its broad partner ecosystem, customers can better predict and shape demand, transform product delivery, fulfill more intelligently, grow revenue and profits, and deliver superior customer experiences.

BlueYonder’s proven solutions power an Autonomous Supply ChainTM for 4,000 of the world’s leading companies including 75 of the top 100 retailers, 77 of the top 100 consumer goods companies, and 8 of the top 10 global 3PLs.

Management Levels

Total Turnover

Join over 180 participants that have so far taken part in the manufacturing survey and more than 100 organisations that have participated in the retail program.

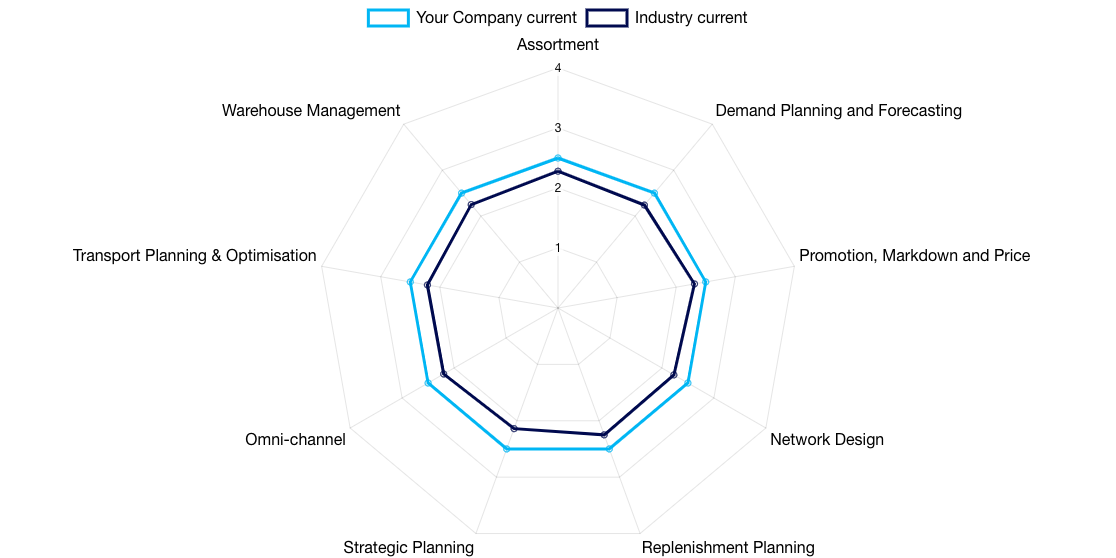

Supply chain processes: current readiness vs industry

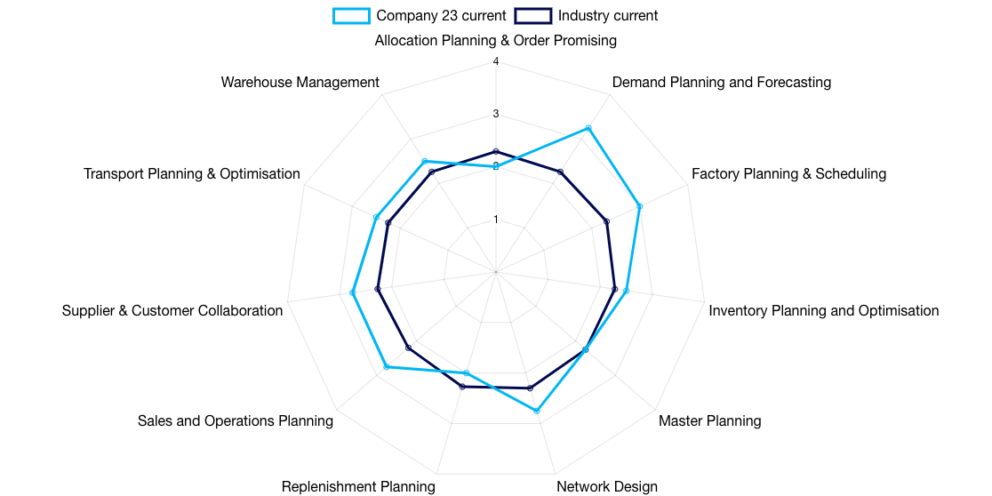

Supply chain processes: current readiness vs industry

To conduct the survey, the supply chain was broken down into core processes, from which a mission-specific maturity grid was developed for each. Participants were asked to identify their current maturity levels and their ambitions for five years’ time, and from those parameters an overall aggregate score was calculated. This methodology enabled patterns in digital maturity to be identified in correlation with ambition and strategic gap analysis.